Buying the wrong HPMC for your tile adhesive can waste thousands of dollars and cause product failures. Many manufacturers face this problem due to confusing technical specifications and misleading supplier claims.

To buy HPMC1 for tile adhesive, focus on viscosity (40,000-100,000 mPa.s), methoxyl content (19-24%), hydroxypropyl content (7-12%), and surface treatment status. Choose higher viscosity for vertical applications and consider whether you need surface-treated HPMC based on your production process.

As someone who has supplied HPMC to tile adhesive manufacturers for over 15 years, I've seen the costly mistakes companies make when selecting this crucial ingredient. Let me share what I've learned to help you make better purchasing decisions and avoid these common pitfalls.

The Ultimate Guide on "HPMC Grade" - How to Choose the Right One?

Selecting the wrong HPMC grade can lead to poor adhesion, sagging issues, and wasted materials. Many manufacturers struggle with understanding the technical parameters that matter most.

For tile adhesive applications, you need HPMC with viscosity between 40,000-100,000 mPa.s (measured at 2% solution, 20°C). The methoxyl content should be 19-24%, and hydroxypropyl content 7-12%. These parameters ensure proper water retention, workability, and adhesion strength.

When selecting an HPMC grade for tile adhesive, you must consider several factors beyond just viscosity. The particle size distribution is critical - too fine and you'll face dusting issues, too coarse and it won't dissolve properly. Most tile adhesives benefit from HPMC with 100 mesh particle size, which provides a good balance of dissolution speed and handling properties.

The molecular weight distribution also matters significantly. A more uniform molecular weight distribution leads to more consistent performance. At our factory, we control this parameter carefully through our unique synthesis process. Another important factor is the gel point, which affects when the HPMC becomes active in your mixture. For tile adhesives applied in various temperature conditions, a gel point between 58-65°C is ideal, offering versatility in both summer and winter applications.

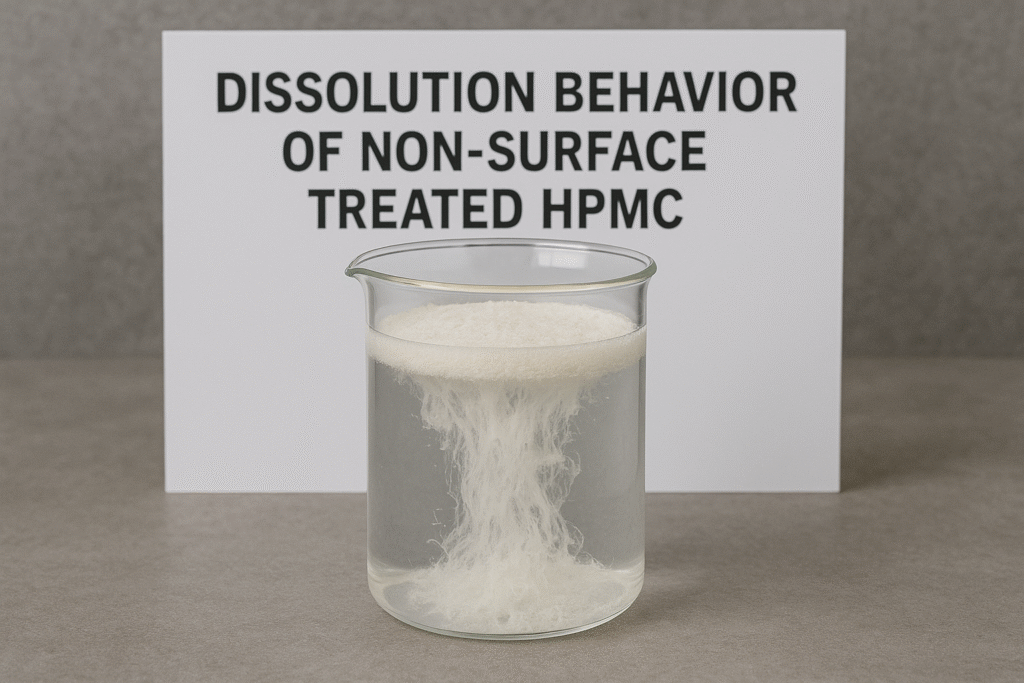

Non-surface treatment HPMC:

Regular HPMC can create lumps when quickly mixed with water. This happens because the outer layer dissolves fast and forms a gel barrier around the still-dry inner particles.

Non-surface treated HPMC2 dissolves immediately when added to water, making it suitable for manufacturers with specialized mixing equipment that can prevent clumping. This type costs less but requires careful handling during the mixing process to achieve uniform dispersion.

"Dissolution behavior of non-surface treated HPMC")

"Dissolution behavior of non-surface treated HPMC")

Non-surface treated HPMC requires specific handling techniques to achieve optimal performance in tile adhesive formulations. When working with this type, I always recommend implementing a two-stage mixing process. First, blend the HPMC thoroughly with the dry components (cement, sand, fillers) before adding water. This creates physical separation between the HPMC particles, reducing their tendency to form lumps when water is added.

The mixing equipment plays a crucial role too - high shear mixers are particularly effective at breaking up any potential clumps. Temperature control is another vital aspect when working with non-surface treated HPMC. If the water temperature exceeds the gel point, you'll experience immediate gelling and poor dispersion. I've found that keeping water temperature 10°C below the gel point provides the best results. While non-surface treated HPMC is more economical, you must consider whether your production setup can accommodate these special handling requirements.

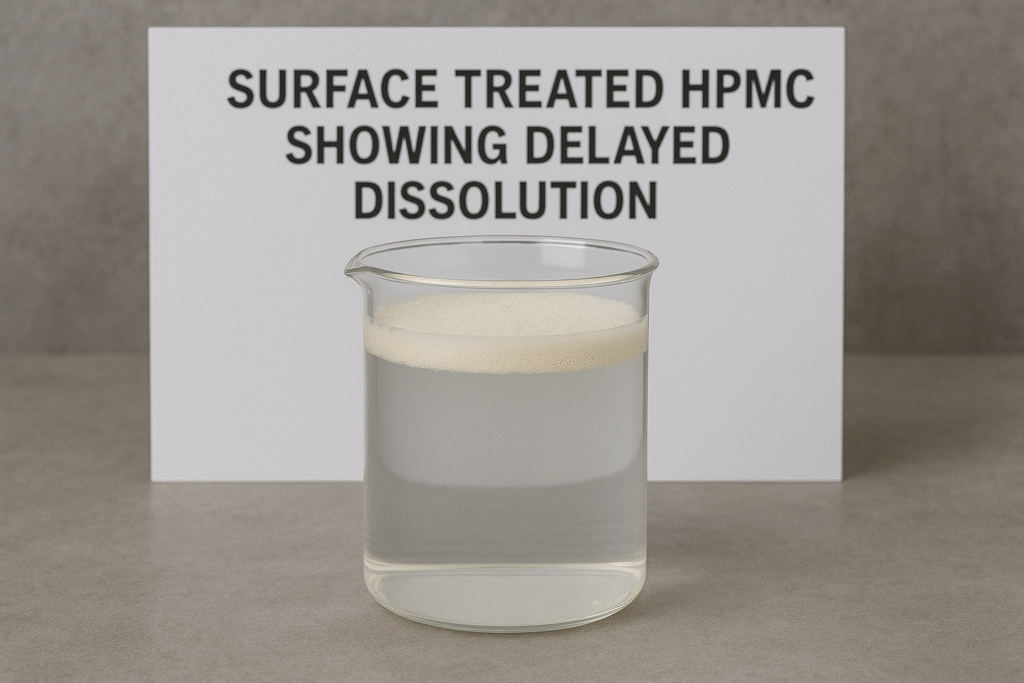

Surface treatment HPMC:

Improper dispersion of HPMC leads to inconsistent tile adhesive performance. Many manufacturers waste time with extended mixing cycles trying to break down lumps.

Surface-treated HPMC has a protective coating that delays dissolution until the particles are fully dispersed in water. This "hot-cold" or "controlled dissolution" technology prevents lumping, making it ideal for simple mixing processes or when using cold water. It typically costs 5-10% more than non-treated HPMC.

Surface treatment technology has evolved significantly in recent years, with several variations now available in the market. The traditional surface treatment method uses organic compounds that create a hydrophobic barrier around each HPMC particle. This barrier temporarily repels water, allowing particles to separate before dissolution begins. More advanced treatments include our proprietary multi-layer coating system, which provides better controlled dissolution even under challenging mixing conditions.

When selecting surface-treated HPMC, you should consider not just the presence of surface treatment, but the quality of that treatment. Lower-quality surface treatments may create uneven dissolution profiles, where some particles dissolve immediately while others remain undissolved even after extended mixing. This leads to inconsistent performance in the final tile adhesive. We test each batch of our surface-treated HPMC using a standardized dispersion test, ensuring that 99% of particles achieve complete dissolution within a specified time window. This high standard ensures your production process remains efficient without sacrificing the performance of your tile adhesive.

HPMC Solutions for Different Application Scenarios of Tile Adhesive?

Tile adhesives for walls vs. floors have different requirements. Using the wrong specification leads to sagging on walls or insufficient bonding strength on floors.

For vertical applications (wall tiles), choose HPMC with higher viscosity (80,000-100,000 mPa.s) to prevent sagging. For floor applications, a medium viscosity (40,000-60,000 mPa.s) provides adequate working time and adhesion. For large-format tiles, use HPMC with extended open time properties3.

Beyond just viscosity, the cellulose ether's fine-tuned properties significantly impact tile adhesive performance in different scenarios. For bathroom and kitchen applications where moisture resistance is crucial, I recommend HPMC with higher hydroxypropyl content4 (10-12%), which enhances the adhesive's water resistance properties. This has proven particularly valuable for clients working on commercial kitchen projects where constant exposure to water and steam is expected.

For outdoor applications, we've developed specialized HPMC grades with enhanced temperature stability. These grades maintain consistent performance between 5-40°C, important for adhesives that must cure in varying weather conditions. When working with porous tiles like natural stone, water retention becomes even more critical. Our high-retention grade (with water retention value >95%) prevents excessive moisture absorption into the tile, which can cause staining and weakened bonds. For fast-setting tile adhesives, we modify the dissolving profile of our HPMC1 to ensure it releases its water-retaining properties quickly but maintains them long enough for proper cement hydration. This customization allows for project completion in half the traditional waiting time without compromising quality.

HPMC Production Process - Why It Matters for Quality?

Poor-quality HPMC leads to inconsistent batch performance in tile adhesives. Many manufacturers don't realize production methods directly impact product stability.

HPMC is produced by reacting alkali cellulose with propylene oxide and methyl chloride. The quality depends on reaction control precision, purification processes, and quality of raw cellulose. Advanced manufacturers use automated reactors with precise temperature and pressure control to ensure consistent quality.

The production process influences virtually every performance aspect of the final HPMC product. The source of cellulose is the foundation of HPMC quality - we select high-purity cotton linters or specialty wood pulp with controlled fiber length and minimal impurities. During the alkalization stage, the concentration and temperature of the sodium hydroxide solution critically affect the reactivity of cellulose. Our process uses precise concentration control (±0.1%) and temperature regulation (±1°C) to ensure consistent activation of cellulose hydroxyl groups.

The etherification stage is where the most significant quality differences emerge between manufacturers. Our reactor design enables homogeneous reaction conditions throughout the vessel, eliminating "hot spots" that can lead to degraded product or inconsistent substitution patterns. We monitor the reaction kinetics in real-time, adjusting reagent flow rates as needed to maintain optimal reaction conditions. After synthesis, the purification process removes by-products and unreacted materials. Our multi-stage washing system reduces salt content below 0.5%, preventing potential issues with cement setting time in the final tile adhesive. The drying and milling processes are equally important - we use fluid bed technology with precisely controlled air flow and temperature profiles to achieve uniform moisture content (±0.3%) across the entire batch, ensuring consistent performance in your application.

Factors Affecting HPMC Price - What's Behind the Numbers?

Prices for HPMC can vary widely, leaving buyers confused about value. Many end up overpaying for specifications they don't need or choosing cheaper products that underperform.

HPMC pricing is determined by viscosity (higher viscosity costs more), surface treatment (adds 5-10%), purity level, packaging requirements, order volume, and market conditions. Prices typically range from $2.5-$4.5/kg for tile adhesive grades, with higher viscosity grades at the upper end.

The relationship between price and performance isn't always linear in the HPMC market. Raw material costs, particularly cellulose pulp and process chemicals, comprise about 60-70% of the final product cost. Market fluctuations in these materials can cause significant price variations throughout the year. The manufacturing efficiency factor also substantially impacts pricing - older production facilities often have higher energy consumption and lower yields, resulting in higher costs despite potentially lower quality output.

Geographic considerations play a role too - transportation costs can add $0.2-0.4/kg depending on destination and shipping method. We've optimized our logistics network to minimize these costs, passing savings on to our customers. Regulatory compliance has become increasingly important in recent years, with different markets requiring specific certifications (REACH, ISO, etc.). Fully compliant products may cost more but eliminate the risk of regulatory issues in your finished goods. When evaluating HPMC suppliers, consider the total cost of ownership rather than just the per-kilogram price. A slightly more expensive product that offers better dissolution properties could reduce your mixing time and energy costs, while more consistent quality reduces waste from rejected batches. One of our customers found that switching to our premium grade actually reduced their overall production costs by 7% despite a 15% higher material cost, due to these efficiency improvements.

Melacoll VS Other Brands - How We Compare?

With so many HPMC brands available, it's hard to know which offers the best value. Some manufacturers make claims their products can't deliver on.

Kehao's Melacoll HPMC offers excellent batch-to-batch consistency (viscosity variation <3%), superior water retention (>95%), and technical service with formulation support. Our production capacity of 15,000 tons annually ensures stable supply, while our direct factory model provides competitive pricing without distributor markups.

As the chief quality officer at Kehao, I personally oversee our testing protocols to ensure Melacoll maintains its reputation for consistency. Each production batch undergoes 22 different quality tests before release, compared to the industry average of 7-12 tests. This comprehensive quality control system is why our customers report 40% fewer adjustments to their formulations when using Melacoll versus competing brands.

Our research department works continuously to improve our products, incorporating customer feedback into our development process. For example, when several tile adhesive manufacturers in hot climate regions reported workability issues, we developed a specialized grade with extended open time specifically for these markets. This customer-driven innovation approach has led to several proprietary improvements in our production process. Our technical support extends beyond just selling HPMC - we offer complete formulation assistance, helping customers optimize their entire tile adhesive formula for cost and performance. This consultative approach has helped many of our clients reduce their overall formulation costs by 5-15% while maintaining or improving performance. Additionally, our vertical integration with some raw material production gives us greater control over quality and costs, advantages we pass on to our customers through more stable pricing and reliable supply even during market disruptions.

HPMC VS HEMC - Which is Better for Your Tile Adhesive?

Choosing between HPMC and HEMC can be confusing. Making the wrong choice based on price alone might compromise your tile adhesive's performance.

HPMC (hydroxypropyl methylcellulose) provides better water retention and adhesion strength for tile adhesives compared to HEMC (hydroxyethyl methylcellulose). While HEMC5 is typically 5-15% cheaper, HPMC creates more stable viscosity under various temperatures and offers better sag resistance for wall applications.

[^5] for tile adhesive applications HPMC vs HEMC comparison](https://xhhpmc.com/wp-content/uploads/2025/08/ChatGPT-Image-2025%E5%B9%B48%E6%9C%8821%E6%97%A5-14_21_34-1024x683.png)

The molecular structure difference between HPMC and HEMC creates significant performance variations that impact tile adhesive behav

Temperature stability represents another key difference - our laboratory tests show that HPMC maintains more consistent viscosity across a temperature range of 5-40°C, while HEMC exhibits greater viscosity fluctuations with temperature changes. This stability is particularly important for applications in regions with significant daily temperature variations or for products used in both indoor and outdoor settings. The workability profile also differs significantly - HPMC provides a longer open time by about 15-25%, giving installers more flexibility during tile placement. While the initial cost of HEMC is lower, we've documented cases where manufacturers switched from HPMC to HEMC only to increase dosage rates by 10-30% to achieve comparable performance, negating potential cost savings. For premium tile adhesive formulations, especially those requiring C2TE classification (enhanced slip resistance, extended open time), HPMC remains the optimal choice despite the higher initial investment.

Why Do You Need HPMC in Dry Mix Mortar?

Many manufacturers don't fully understand the role of HPMC in tile adhesives, leading to improper usage or substitution with cheaper alternatives that fail.

HPMC serves four critical functions in tile adhesives: it retains water for proper cement hydration, improves workability and adhesion, prevents tiles from slipping on vertical surfaces, and extends open time for adjustment. Without it, tile adhesives would dry too quickly, reducing bond strength and workability.

The mechanisms by which HPMC enhances tile adhesive performance are fascinating from a chemical perspective. When water is added to a dry mix formulation containing HPMC, the cellulose ether molecules begin to hydrate and unfold, forming a three-dimensional network throughout the paste. This network functions as a physical water reservoir, slowly releasing moisture over time. On a microscopic level, HPMC molecules actually attach themselves to both the cement particles and the surface of the tile, creating polymer bridges that enhance adhesion beyond what cement alone could achieve.

The thixotropic behavior imparted by HPMC is particularly valuable - when force is applied (during spreading), viscosity decreases, making the adhesive easy to work with, but when force is removed, viscosity increases again, preventing sag. We've measured this effect in our laboratories, finding that properly formulated HPMC can increase sag resistance by up to 300% compared to formulations without it. Additionally, HPMC interacts with other additives in synergistic ways - for example, it enhances the effectiveness of redispersible polymer powders6 by maintaining the proper moisture conditions for film formation. It also helps prevent segregation of components during shipping and storage of dry mix products. In summary, while HPMC7 typically represents only 0.2-0.5% of a tile adhesive formulation by weight, it fundamentally transforms the material's behavior, enabling the high performance expected in modern construction.

Conclusion

Choosing the right HPMC for your tile adhesive is crucial for product performance and profitability. Focus on viscosity, methoxyl content, surface treatment, and application-specific requirements to make the best decision for your needs.

-

Understanding HPMC is crucial for selecting the right type for your tile adhesive needs. ↩ ↩

-

Surface treated HPMC can simplify mixing; learn how it can improve your process. ↩

-

Open time properties affect application; learn how to select the right HPMC for your project. ↩

-

Hydroxypropyl content is vital for water retention; explore its effects on adhesion. ↩

-

Choosing the right cellulose ether is crucial; compare HPMC and HEMC for your needs. ↩

-

Find out how redispersible polymer powders work with HPMC to improve tile adhesive performance. ↩

-

Explore the advantages of HPMC in tile adhesives to understand its critical role in enhancing performance and workability. ↩