As a factory owner in the construction materials industry, I've seen many builders struggle with material selection. They want products that set quickly, perform well, and maintain safety standards, but the overwhelming options leave them confused and frustrated.

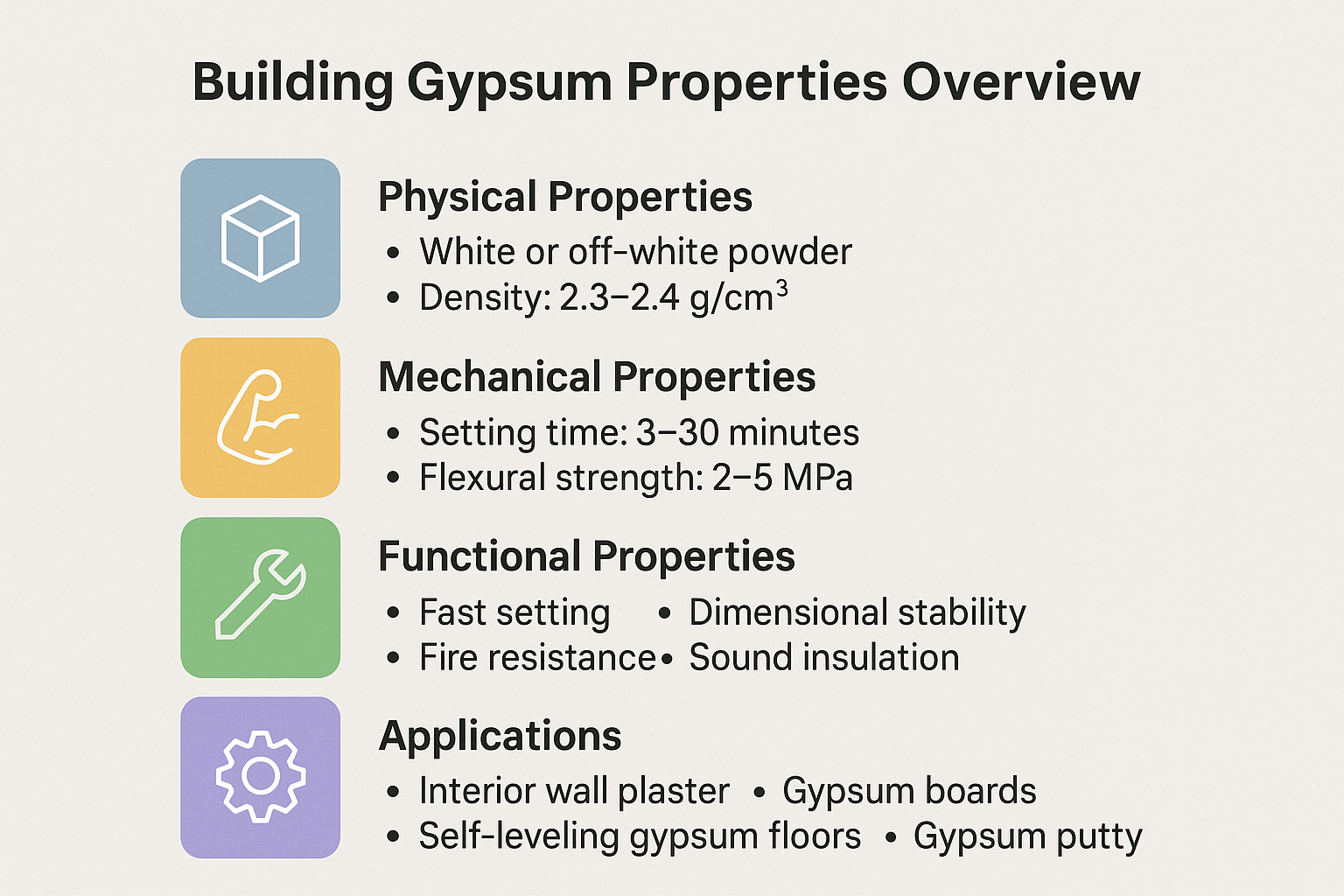

Building gypsum1 is a versatile construction material with rapid setting properties (typically 10-45 minutes), excellent fire resistance (withstanding temperatures up to 1200°C), humidity regulation capabilities, and slight expansion during setting that prevents cracking. However, it has limited water resistance.

When choosing materials for construction projects, understanding the key properties of each option is essential. Building gypsum offers unique characteristics that make it suitable for specific applications, but not for others. Let's examine these properties in detail to help you make informed decisions for your next project.

Introduction: Why Is Building Gypsum Popular In Construction?

Every construction project I've consulted on has faced the same challenge: finding materials that balance performance, cost, and application ease. Many clients have wasted money on inappropriate materials simply because they didn't understand the basic properties.

Building gypsum is popular because it sets quickly (within minutes rather than hours), creates a comfortable indoor climate by absorbing excess humidity, offers excellent fire protection, and is significantly lighter than cement-based materials while providing good sound insulation.

Building gypsum1 has been used for thousands of years, dating back to ancient Egypt where it was used in the construction of pyramids. Today, it remains one of the most widely used building materials worldwide due to its unique combination of properties. Unlike many other construction materials, building gypsum is relatively eco-friendly as it requires less energy to produce compared to cement and can be recycled.

The chemical composition of gypsum2 (calcium sulfate dihydrate - CaSO₄·2H₂O) gives it distinctive properties that make it invaluable for interior construction. When heated, gypsum loses its water molecules and becomes plaster of Paris (calcium sulfate hemihydrate), which can then be mixed with water to reform gypsum in any desired shape. This transformation process is key to understanding gypsum's behavior in construction applications.

| Different grades of building gypsum are available for specific applications: | Grade | Setting Time | Common Applications |

|---|---|---|---|

| Alpha plaster | Slower setting, higher strength | Molds, models, special plasters | |

| Beta plaster | Quicker setting, standard strength | Wall plasters, drywall production | |

| Final setting plaster | Minimal expansion | Finishing coats |

Fast Setting And Hardening: How Quickly Does Building Gypsum Work?

On several renovation projects, we faced tight deadlines that seemed impossible. Many traditional materials would have caused major delays, putting the entire project timeline at risk.

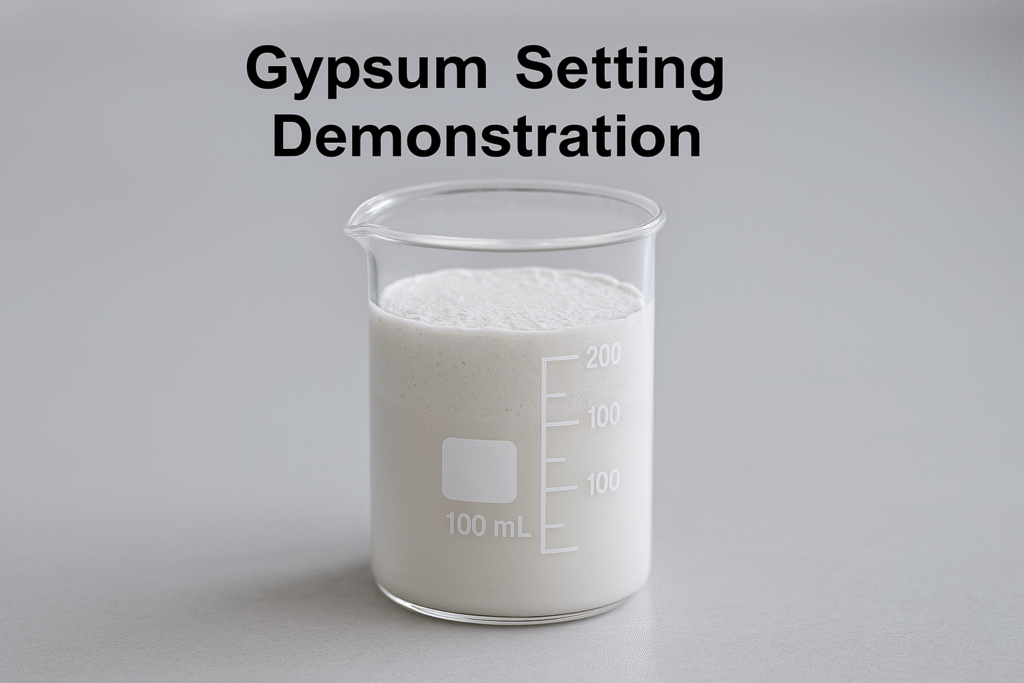

Building gypsum1 typically sets within 10-45 minutes after mixing with water and achieves about 80% of its final strength within 1-2 hours, making it ideal for rapid construction work and repairs where quick turnaround is essential. Different additives can control this setting time.

The remarkable setting and hardening properties of building gypsum are due to its chemical reaction with water. When water is added to calcined gypsum (CaSO₄·½H₂O), it rehydrates to form gypsum crystals (CaSO₄·2H₂O) again. This recrystallization process creates an interlocking matrix of needle-like crystals that give the hardened material its strength.

This rapid setting characteristic makes gypsum particularly valuable in applications where time is a critical factor. For interior finishing work, this property allows multiple layers to be applied in a single day - something impossible with most cement-based products that require 24-hour curing periods between applications.

However, the setting time can be manipulated to suit different applications. Retarders can extend working time for more complex applications, while accelerators can speed up setting for urgent repairs. Common setting time modifiers include:

- Retarders: citric acid, proteins, and some commercial products

- Accelerators: potassium sulfate, sodium chloride, and alum

The temperature and humidity of the environment also significantly affect setting time, with warmer conditions generally accelerating the process. Professional applicators must take these factors into account when planning gypsum installation to ensure optimal results.

Humidity Regulation Capability: How Does Gypsum Affect Indoor Climate?

I've visited countless buildings with poor ventilation systems where humidity issues caused mold growth and respiratory problems. Residents were constantly battling condensation and the associated health risks.

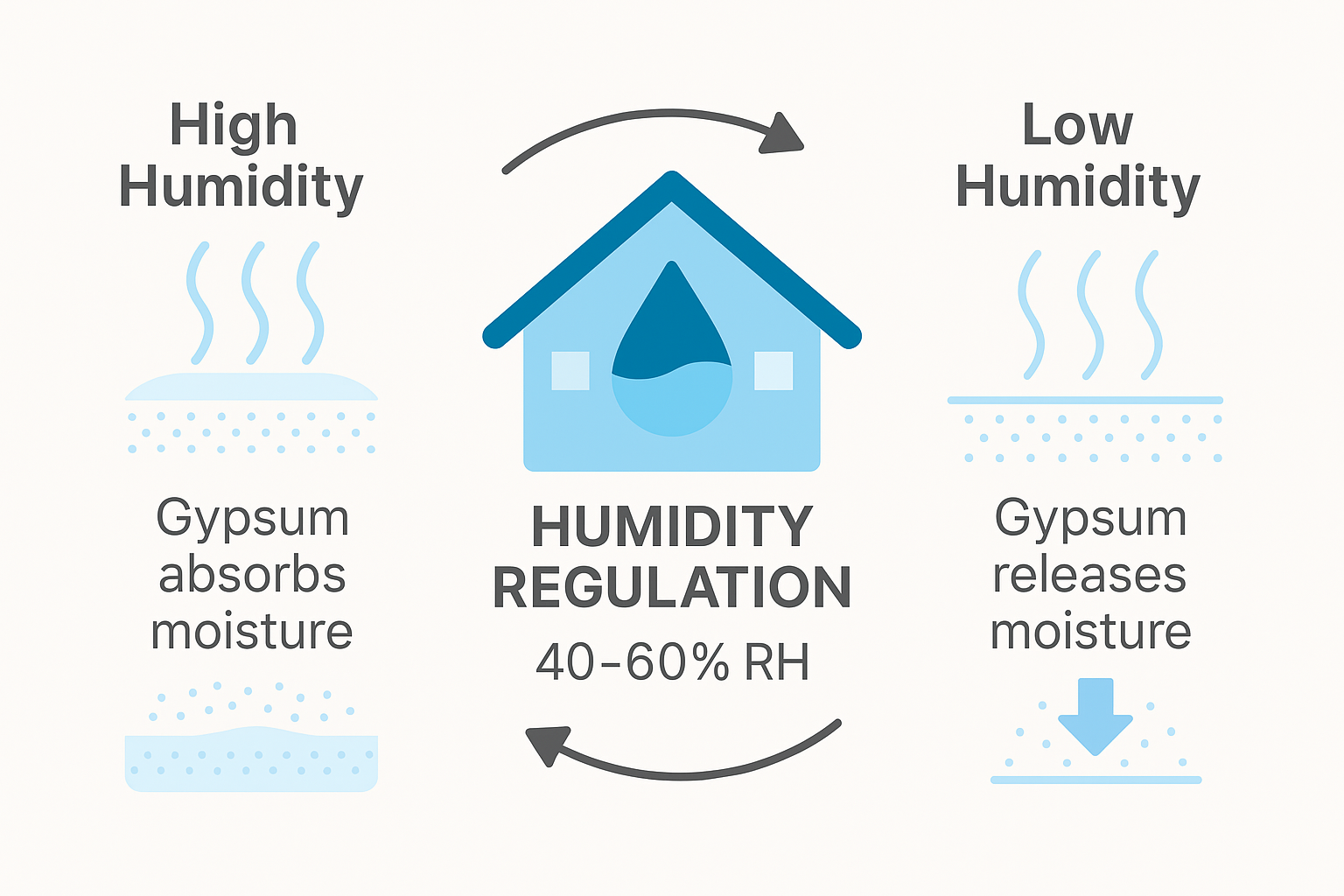

Building gypsum naturally regulates humidity by absorbing excess moisture when indoor air is humid and releasing it when the air becomes dry, helping maintain indoor relative humidity between 40-60%, which is the optimal range for human comfort and health.

This remarkable humidity-regulating property makes gypsum an excellent material for creating healthier indoor environments. The microscopic structure of gypsum contains numerous pores that can capture and release water molecules as environmental conditions change. In technical terms, gypsum acts as a hygroscopic buffer, moderating humidity fluctuations without requiring any energy input or maintenance.

Studies have shown that rooms finished with gypsum-based materials typically experience 30-40% less humidity variation compared to those finished with non-absorbent materials. This stability has significant benefits for both human health and building preservation. For occupants, maintaining humidity in the optimal 40-60% range reduces the risk of respiratory issues, allergies, and skin problems. For the building itself, avoiding extreme humidity levels helps prevent condensation, mold growth, and deterioration of other building materials and furnishings.

The humidity regulation effect works most effectively when:

- The gypsum surface remains unpainted or is finished with breathable coatings

- There is adequate air circulation in the room

- The gypsum layer is of sufficient thickness (typically minimum 10mm)

This property is particularly valuable in bathrooms, kitchens, and basements - areas that typically experience significant humidity fluctuations. In climates with seasonal humidity changes, gypsum-finished interiors help reduce reliance on mechanical humidification or dehumidification systems, potentially saving energy and associated costs.

Excellent Fire Resistance: Why Is Gypsum Used In Fire Protection?

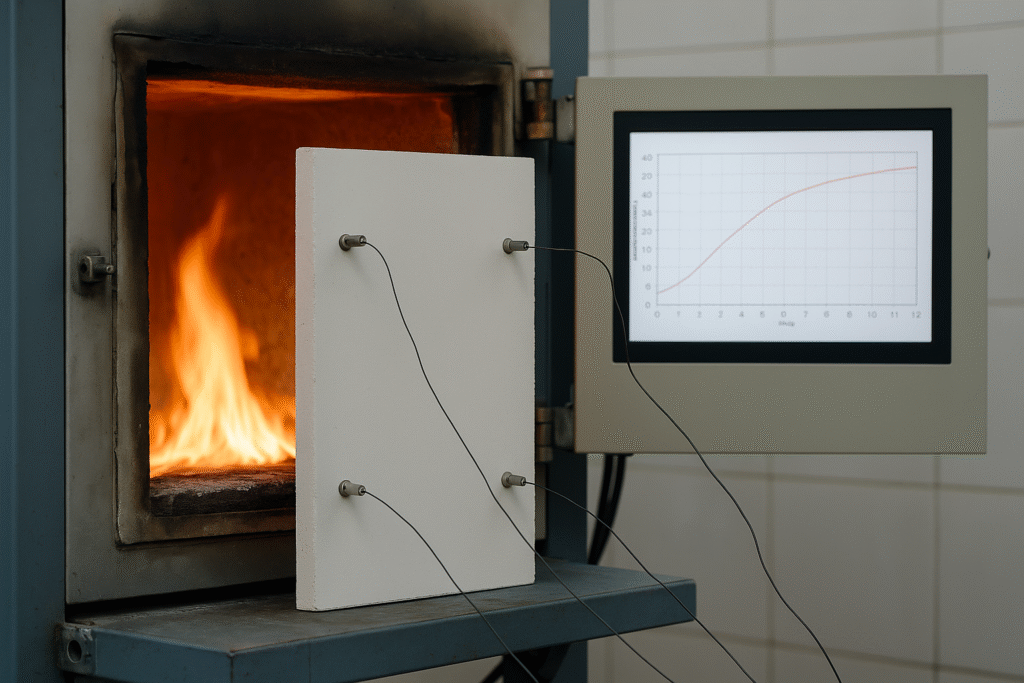

During a factory inspection last year, I witnessed a demonstration that changed my perspective on safety materials. A gypsum wall panel was subjected to direct flame for an hour and maintained its integrity, while other materials failed within minutes.

Building gypsum offers exceptional fire resistance by containing chemically bound water (about 21% by weight) that releases as steam when exposed to fire, absorbing heat and maintaining temperatures around 100°C until dehydration completes, providing up to 120 minutes of protection.

The fire resistance of gypsum is one of its most valuable safety properties, making it a critical component in passive fire protection strategies in building construction. When gypsum is exposed to fire, it undergoes a process called calcination. The chemically bound water molecules in gypsum (CaSO₄·2H₂O) require significant heat energy to convert to steam, creating an effective heat sink that slows temperature rise on the unexposed side of a gypsum-based system.

This characteristic makes gypsum board3 (drywall) the material of choice for fire-rated assemblies in modern construction. Fire-rated gypsum boards typically contain additional materials like glass fibers that help maintain structural integrity even after the gypsum has calcined. Multiple layers of gypsum board can achieve fire ratings of up to 4 hours in properly designed systems.

The effectiveness of gypsum in fire protection can be quantified:

| Gypsum Product Type | Typical Fire Rating (single layer) | Temperature Resistance |

|---|---|---|

| Standard drywall (12.5mm) | 30 minutes | Up to 800°C |

| Type X fire-resistant board (15mm) | 60 minutes | Up to 1000°C |

| Type C enhanced fire board (15mm) | 60-90 minutes | Up to 1200°C |

| Multiple layer systems | Up to 240 minutes | Up to 1200°C |

Fire resistance testing is standardized globally, with tests measuring how long a gypsum assembly can maintain its integrity and insulation properties during a standardized fire exposure. This predictable performance allows architects and engineers to design buildings with quantifiable safety margins, potentially saving lives by providing crucial evacuation time during fire emergencies.

No Shrinkage, Slight Expansion: How Does This Affect Construction?

Early in my career, I worked on a project where concrete shrinkage caused extensive cracking, requiring costly repairs. The contractor mentioned that using gypsum-based materials4 for certain interior elements would have prevented these issues.

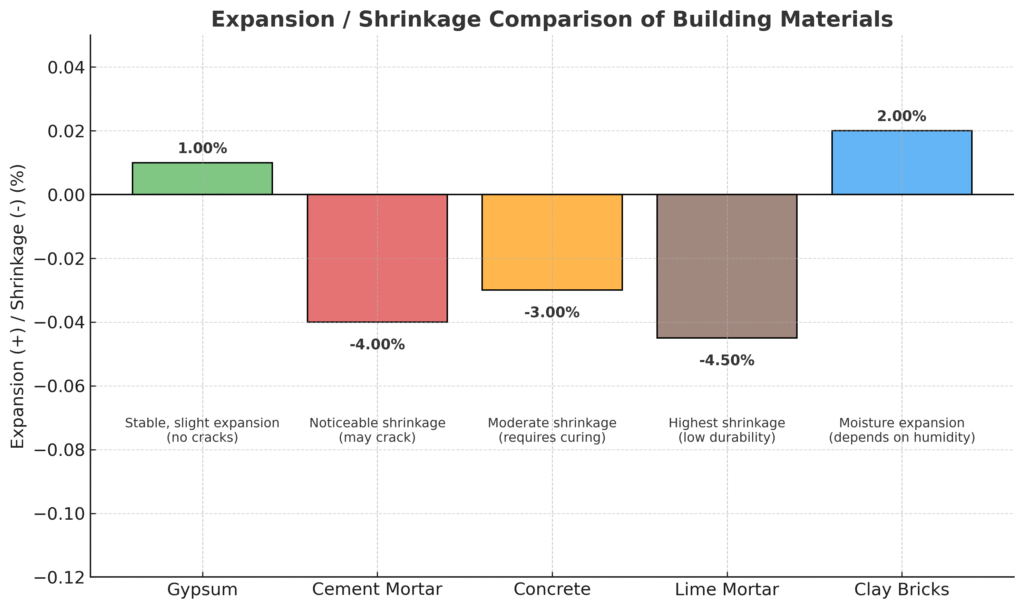

Unlike cement-based materials that shrink during setting, building gypsum expands slightly (approximately 0.15-0.30%) during hardening, creating tight joints and ensuring complete filling of molds and cavities without cracking or pulling away from substrates.

This unique property of slight expansion during setting gives gypsum a significant advantage in many applications, particularly in creating precise casts, molds, and decorative elements. The expansion helps gypsum capture fine details and produces sharp, clean edges that would be difficult to achieve with materials that shrink during curing.

The dimensional stability of gypsum comes from the crystal structure formed during setting. As gypsum rehydrates, the growing crystals interlock and create a slight pressure outward. This expansion is carefully controlled in commercial products, as excessive expansion could be problematic. Manufacturers adjust the expansion properties by controlling calcination conditions and through additives that modify crystal growth.

This property is particularly valuable in:

- Cast ornamental elements: The slight expansion ensures that all details of a mold are captured precisely

- Jointing compounds: The expansion helps fill gaps completely without subsequent cracking

- Self-leveling compounds: Gypsum-based floor leveling products maintain contact with the subfloor

- Repair work: When filling cracks or holes, the expansion ensures complete filling without future separation

However, this expansion must be accommodated in design. For large continuous gypsum installations, expansion joints are necessary to prevent buckling or cracking. The typical recommendation is an expansion joint every 9 meters in large gypsum installations.

For specialty applications requiring extremely precise dimensions, special alpha gypsum plasters with minimal expansion are available, though these typically come at a higher cost and with longer setting times.

Lightweight And Insulating: What Advantages Does This Provide?

During a recent renovation project, we needed to add partitions to an older building where floor load capacity was a concern. The engineer immediately recommended gypsum-based systems5 because of their significantly lower weight compared to masonry alternatives.

Building gypsum products are approximately 3-4 times lighter than concrete (typical density 700-1000 kg/m³ vs. 2400 kg/m³ for concrete), reducing structural load while providing good thermal insulation (λ-value around 0.25 W/mK) and excellent acoustic insulation properties.

The lightweight nature of gypsum construction systems offers multiple advantages throughout the building lifecycle. During construction, lightweight materials reduce labor fatigue, speed up installation, lower transportation costs, and decrease the need for heavy machinery. For the completed building, the reduced dead load on the structure can allow for more flexible architectural designs or smaller structural elements.

The insulating properties of gypsum stem from its porous microstructure, which contains numerous tiny air pockets. These air pockets disrupt heat transfer pathways, giving gypsum significantly better thermal performance than more dense building materials. While not as effective as dedicated insulation materials like mineral wool or polystyrene, the inherent insulation value of gypsum contributes to the overall thermal performance of wall assemblies.

The acoustic performance of gypsum-based systems5 is particularly noteworthy. When properly installed in multi-layer systems with acoustic insulation, gypsum board partitions can achieve Sound Transmission Class (STC) ratings6 of 50 or higher, effectively blocking most conversational sound. This sound-damping quality comes from gypsum's density combined with its slight flexibility, which helps absorb sound vibrations rather than transmitting them.

Comparative weight and insulation values:

| Material | Typical Density (kg/m³) | Thermal Conductivity (W/mK) |

|---|---|---|

| Building gypsum | 700-1000 | 0.25-0.4 |

| Concrete | 2200-2400 | 1.4-1.7 |

| Clay brick | 1400-2000 | 0.6-1.0 |

| AAC block | 400-800 | 0.12-0.18 |

The lightweight nature of gypsum also makes it easier to create prefabricated elements that can be rapidly installed on-site, contributing to modern methods of construction that emphasize speed and efficiency. This property has made gypsum-based systems increasingly popular in fast-track construction projects where time is a critical factor.

Poor Water And Frost Resistance: What Are The Limitations?

I once inspected a building where someone had used regular gypsum plaster in an external area exposed to rain. Within months, the entire installation had deteriorated, requiring complete replacement with appropriate water-resistant materials.

Standard building gypsum has poor resistance to prolonged moisture exposure, losing up to 50% of its strength when saturated with water, and is unsuitable for exterior use or permanently damp areas unless specially formulated water-resistant versions are used.

The poor water resistance of standard gypsum is its most significant limitation. When exposed to water, the hardened gypsum can reabsorb moisture, which weakens the crystal matrix that provides its strength. Additionally, wet gypsum can become a substrate for mold growth if not dried quickly and thoroughly.

This vulnerability to water damage restricts gypsum use primarily to interior applications protected from weather and plumbing leaks. For areas with occasional moisture exposure like bathrooms and kitchens, specially formulated moisture-resistant gypsum boards7 (often called "greenboard" due to their color) are available. These products incorporate water-repellent additives in the gypsum core and water-resistant facings, but are still not suitable for constantly wet areas or exterior applications.

For areas requiring water resistance, various modifications to standard gypsum have been developed:

- Moisture-resistant boards: Contain silicone or other water-repellent additives

- Cement-coated gypsum boards: Combine gypsum core with cement board facing for improved durability

- Glass-mat gypsum panels: Replace paper facing with fiberglass mats for superior moisture resistance

- Gypsum-cement blends: Incorporate Portland cement to improve water resistance

Even with these modifications, no gypsum-based product is completely waterproof, and alternative materials should be considered for:

- Exterior applications exposed to weather

- Areas subject to standing water or frequent wetting

- Below-grade installations without proper waterproofing

- Frost-prone environments where freeze-thaw cycles occur

The frost resistance of gypsum is particularly poor because the absorbed water expands upon freezing, disrupting the crystal structure and causing rapid deterioration. Multiple freeze-thaw cycles can reduce even high-quality gypsum products to powder in relatively short periods.

Understanding these limitations is crucial for proper material selection and preventing costly failures in inappropriate applications. Always verify manufacturer recommendations for specific environmental conditions before selecting gypsum products.

Summary

Building gypsum offers rapid setting, excellent fire resistance, humidity regulation, and slight expansion during setting, making it ideal for interior construction. It's lightweight and insulating but has poor water resistance, limiting it to dry interiors unless specially formulated for moisture exposure.

-

Explore the advantages of building gypsum, including its rapid setting and eco-friendly properties, to enhance your construction projects. ↩ ↩ ↩

-

Explore the unique chemical properties of gypsum that make it a valuable material in construction. ↩

-

Learn about the benefits of gypsum board, including its fire resistance and ease of installation. ↩

-

Explore the advantages of gypsum-based materials for various construction applications and their unique properties. ↩

-

Explore the advantages of gypsum-based systems, including their lightweight nature and insulation properties, which can enhance your building projects. ↩ ↩

-

Learn about STC ratings to assess soundproofing effectiveness in building materials, crucial for designing quiet environments. ↩

-

Find out how moisture-resistant gypsum boards can protect your interiors from water damage, especially in high-humidity areas. ↩