Are you struggling with inconsistent mortar performance due to air entrainment1 issues? Many mortar manufacturers face this challenge daily, potentially costing thousands in rejected batches and project delays when using hydroxypropyl methylcellulose (HPMC)2.

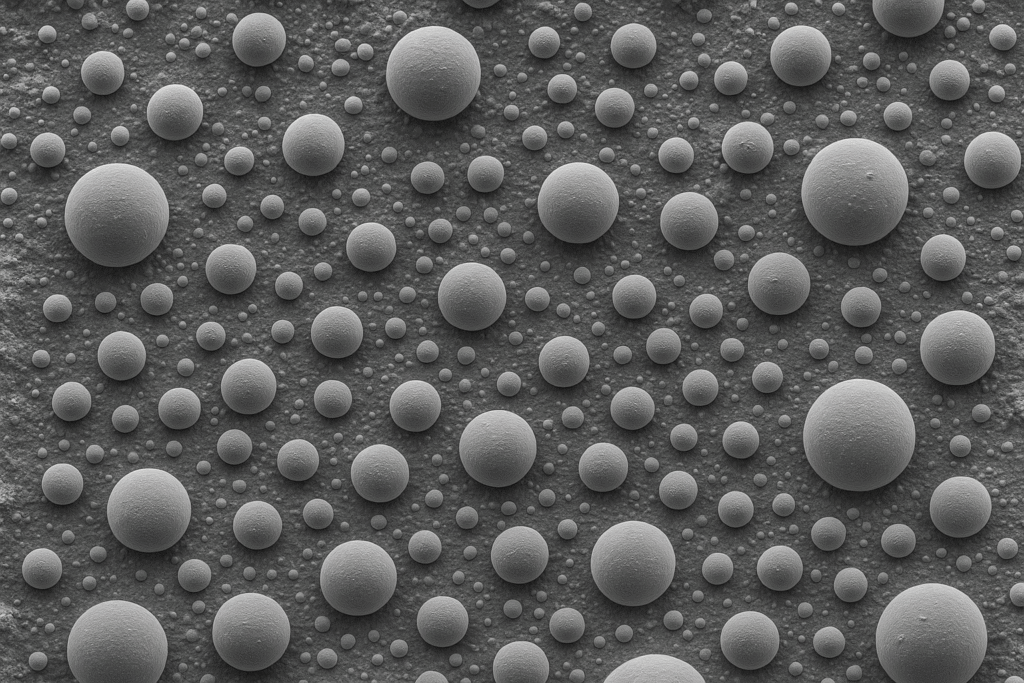

Air entrainment in HPMC refers to the ability of this cellulose ether to create and stabilize microscopic air bubbles within mortar or concrete mixtures. This property significantly impacts workability, freeze-thaw resistance, and overall performance of construction materials by forming a stable network of air voids.

I've been manufacturing HPMC for over 15 years, and I've seen firsthand how critical proper air entrainment is for high-quality construction materials. Let me share what I've learned about the key factors that influence this important property.

What Is Air Entrainment in HPMC and Why Does It Matter?

Have you noticed how some batches of your mortar mix perfectly while others become too foamy or don't hold enough air? This inconsistency often traces back to variations in HPMC air entrainment properties.

Air entrainment in HPMC is the process where the polymer creates and stabilizes microscopic air bubbles (10-1000μm) within mortar mixtures. These bubbles improve workability, prevent bleeding and segregation, enhance freeze-thaw durability, and affect final strength properties of construction materials.

The air entraining capability of HPMC isn't a fixed property but rather a dynamic characteristic influenced by multiple factors. When I first started producing HPMC, I assumed molecular weight was the only important factor. However, after thousands of production batches, I discovered the reality is much more complex.

Molecular weight certainly plays a critical role in determining air entrainment properties. Higher molecular weight HPMC typically creates more stable air bubbles due to increased solution viscosity and enhanced surface activity. Our high-viscosity HPMC grades (100,000 mPa·s and above) consistently demonstrate superior air-stabilizing properties compared to lower viscosity varieties.

However, molecular weight is just one piece of the puzzle. The degree of substitution (DS)3 - specifically the ratio of methoxy to hydroxypropyl groups - significantly impacts air entrainment. HPMC with higher methoxy content tends to be more hydrophobic, creating stronger interactions at air-water interfaces and thus better air entrainment. In contrast, higher hydroxypropyl substitution increases water solubility but may reduce air entrainment efficiency.

Particle size distribution is another factor that's often overlooked but critically important. Finer HPMC particles dissolve more rapidly in water, leading to faster development of air entrainment properties. In our testing labs, we've observed that HPMC with uniform particle distribution around 80-100 mesh shows optimal dissolution rates and consistent air entrainment.

How Do Formulation Compatibility Factors Impact HPMC Air Entrainment?

Does your mortar formulation sometimes behave unpredictably despite using the same HPMC grade? The compatibility with other ingredients might be affecting your air entrainment properties more than you realize.

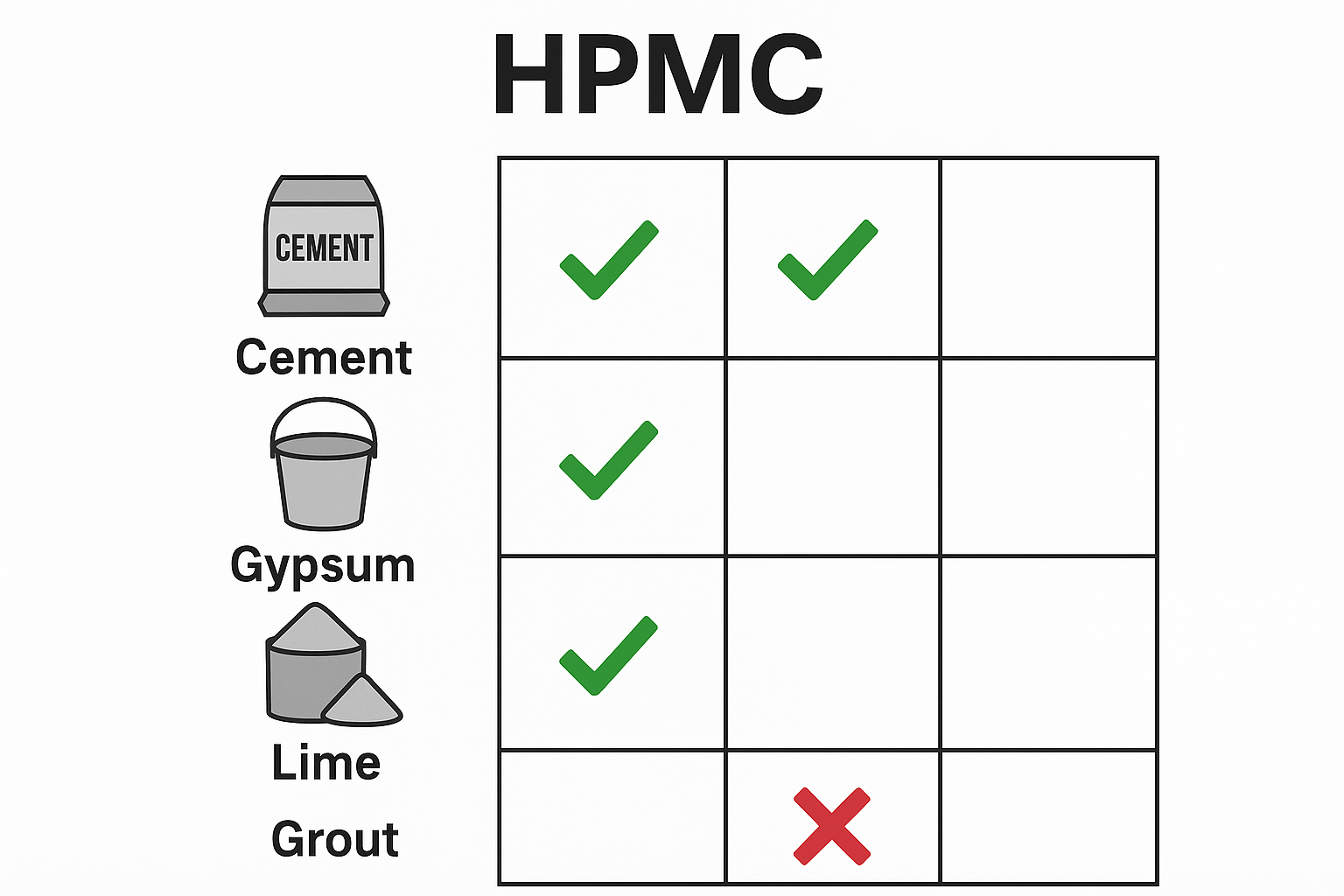

Formulation compatibility significantly impacts HPMC air entrainment. Cement alkalinity, presence of defoamers, aggregate type and gradation, and other additives like redispersible powders4 all interact with HPMC to either enhance or diminish its air-entraining capabilities, requiring careful balance for optimal performance.

The complex chemistry behind HPMC interactions with other formulation components can dramatically alter air entrainment behavior. In my experience working with customers across diverse climatic conditions, I've identified several key compatibility factors that construction professionals should monitor carefully.

Cement type and alkalinity level create the foundation for HPMC performance. Portland cement's high alkalinity (pH 12-13) affects HPMC dissolution kinetics and consequently its air entrainment capabilities. We've observed that higher alkaline environments can accelerate HPMC hydration but may also lead to premature gelation, potentially reducing air entrainment effectiveness over time. During a project in the UAE, our customer found that blended cements with lower alkalinity provided more predictable air entrainment with our HPMC products.

The presence and concentration of defoamers represent another critical factor. While defoamers are often added to control excessive air content, they directly counteract HPMC's air entrainment properties. Finding the optimal balance requires precise dosage control. Our laboratory tests consistently show that exceeding 0.05% defoamer concentration can significantly diminish HPMC air entrainment benefits, particularly in thin-set mortars where air content affects both workability and bond strength.

Aggregate type and gradation also play surprising roles in air entrainment effectiveness. Angular, rough aggregates tend to puncture air bubbles, reducing entrainment, while smoother, rounded aggregates preserve air void structures better. Additionally, aggregate porosity affects water demand, indirectly influencing HPMC hydration and subsequent air entrainment properties. A comprehensive aggregate gradation analysis can help predict potential air entrainment issues before they arise in field applications.

Finally, the presence of other additives like redispersible polymer powders, superplasticizers, or accelerators can create synergistic or antagonistic effects with HPMC. For example, we've documented that certain polycarboxylate-based superplasticizers can enhance HPMC air entrainment by improving its dispersion, while calcium chloride accelerators may destabilize air bubbles in the mixture.

How Can Processing and Environmental Conditions Optimize HPMC Air Entrainment?

Are unexpected changes in temperature or mixing procedures causing inconsistencies in your mortar performance? Processing and environmental factors have a more significant impact on HPMC air entrainment than most realize.

Processing and environmental conditions greatly affect HPMC air entrainment. Mixing speed and duration, water temperature, ambient temperature, and humidity all influence how HPMC dissolves and entrains air. Optimal results typically require moderate mixing (300-600 RPM), water temperatures between 15-25°C, and controlled humidity conditions.

The effectiveness of HPMC's air entrainment properties doesn't depend solely on its chemical composition but is highly influenced by how it's processed and the environment in which it's used. After analyzing data from over 5,000 customer applications across various climates, I've identified several critical processing variables that significantly impact performance.

Mixing parameters stand out as perhaps the most immediately influential factor. The relationship between mixing energy and air entrainment follows a bell curve pattern—insufficient mixing prevents proper HPMC dissolution and air incorporation, while excessive mixing can cause air bubbles to collapse or coalesce. Our field tests demonstrate that moderate mixing speeds (300-600 RPM) for appropriate durations (3-5 minutes) typically yield optimal air entrainment for most construction applications. High-shear mixing, while speeding dissolution, can actually decrease final air content by breaking down the molecular networks that stabilize air bubbles.

Water and ambient temperatures create another complex variable set. HPMC exhibits temperature-dependent solubility, with most grades showing reduced dissolution rates below 10°C. This "cold water solubility" characteristic means that in colder conditions, air entrainment development is delayed, potentially causing inconsistent workability during application. Conversely, excessively high temperatures (above 35°C) can accelerate HPMC dissolution but may reduce solution viscosity, diminishing air stabilization capacity. We recommend water temperatures between 15-25°C for most balanced performance across applications.

Humidity conditions affect both HPMC powder handling and its performance in the final mixture. In high-humidity environments (>75% RH), HPMC powder can absorb atmospheric moisture, forming "skin" layers that slow dissolution and reduce air entrainment efficiency. This phenomenon becomes particularly problematic in tropical climates like Singapore or Vietnam, where special packaging and handling procedures become necessary to maintain consistent air entrainment properties.

Order of addition in the mixing sequence also proves surprisingly important. Adding HPMC directly to wet components typically results in clumping and incomplete dissolution, reducing air entrainment potential. The preferred method involves pre-blending HPMC with dry components (cement, aggregates) before adding water, allowing for more uniform distribution and subsequent air entrainment. Several of our customers in Saudi Arabia have reported up to 30% improvement in air content consistency simply by optimizing their addition sequences.

How Do Chemical Composition and Purity Impact HPMC Air Entrainment?

Have you ever received HPMC batches that appear identical but perform differently in your applications? The underlying chemical composition and purity differences might be affecting your air entrainment results.

Chemical composition and purity significantly influence HPMC air entrainment properties. Methoxyl to hydroxypropyl substitution ratios, unsubstituted cellulose content, residual salts, and manufacturing byproducts all affect surface activity and consequently air entrainment capability, with purer grades typically providing more consistent results.

The molecular-level characteristics of HPMC create the foundation for all its performance properties, including air entrainment. Through detailed analysis of hundreds of production batches at our manufacturing facility, I've identified several chemical factors that construction material formulators should understand.

Methoxyl to hydroxypropyl substitution ratio represents perhaps the most fundamental chemical characteristic affecting air entrainment. Higher methoxyl content (typically 28-30%) increases hydrophobicity, enhancing HPMC's affinity for air-water interfaces and consequently improving air entrainment capability. Conversely, higher hydroxypropyl substitution improves water solubility but may reduce surface activity. The optimal balance for construction applications typically falls around 28-29% methoxyl content with 7-12% hydroxypropyl content, providing good dissolution characteristics while maintaining strong air entrainment properties.

Unsubstituted cellulose content—often considered an impurity in HPMC—can significantly impact performance. Higher levels of unsubstituted cellulose create dissolution irregularities that interfere with uniform air bubble formation. Our premium HPMC grades maintain unsubstituted cellulose below 2%, ensuring more consistent air entrainment across batches.

Residual salts from the manufacturing process also influence air entrainment more than commonly recognized. Sodium chloride, a byproduct of HPMC production, can affect solution rheology and interfere with the polymer's surface activity when present above certain thresholds (typically >1%). During a troubleshooting case with a major mortar manufacturer in Brazil, we discovered that inconsistent air entrainment was directly correlated to batch-to-batch variations in salt content, which we subsequently standardized through improved purification techniques.

Manufacturing byproducts and unintended side reactions during production can introduce variables affecting air entrainment. For instance, partial thermal degradation during the manufacturing process can reduce molecular weight in unpredictable ways, affecting viscosity and subsequently air stabilization properties. Our six-stage quality control process measures multiple parameters beyond the standard specifications to ensure consistent air entrainment performance.

The presence of hydrophobic contaminants, even in trace amounts, can dramatically alter air entrainment behavior. Substances like mineral oils or silicone-based contaminants introduced during manufacturing or packaging have surfactant-like properties that can either enhance or interfere with HPMC's natural air entraining capabilities, depending on their chemical structure and concentration. These contaminants are particularly problematic because they're not detected by standard quality control tests yet can significantly impact application performance.

Conclusion

The air entraining properties of HPMC depend on a complex interplay of molecular weight, substitution degree, particle size, formulation compatibility, processing conditions, and chemical purity. Understanding these factors helps manufacturers and users optimize HPMC performance in construction applications for more consistent, high-quality results.

-

Understanding air entrainment is crucial for improving mortar performance and preventing costly project delays. ↩

-

Explore how HPMC enhances construction materials, improving workability and durability. ↩

-

Discover how the ratio of methoxy to hydroxypropyl groups influences air entrainment efficiency. ↩

-

Explore the synergistic effects of redispersible powders on HPMC air entrainment. ↩