I've seen many clients struggle with finding the right cellulose ether for their formulations. The inconsistent performance of substandard products often leads to costly rework and project delays.

Sodium Carboxymethyl Cellulose (CMC)1 is a water-soluble, modified cellulose derivative made by reacting alkali cellulose with sodium monochloroacetate. It functions as a thickener, stabilizer, and binder in various industrial applications, providing excellent water retention, viscosity control, and stabilizing properties.

After working with thousands of clients across our six production lines at Kehao, I've noticed how proper understanding of CMC can transform product performance. Let me walk you through everything you need to know about this versatile polymer.

What Makes Sodium Carboxymethyl Cellulose Different From Other Cellulose Ethers?

I often hear confusion from new clients about the differences between various cellulose ethers. Their previous suppliers rarely explained these critical distinctions, resulting in inappropriate product selections.

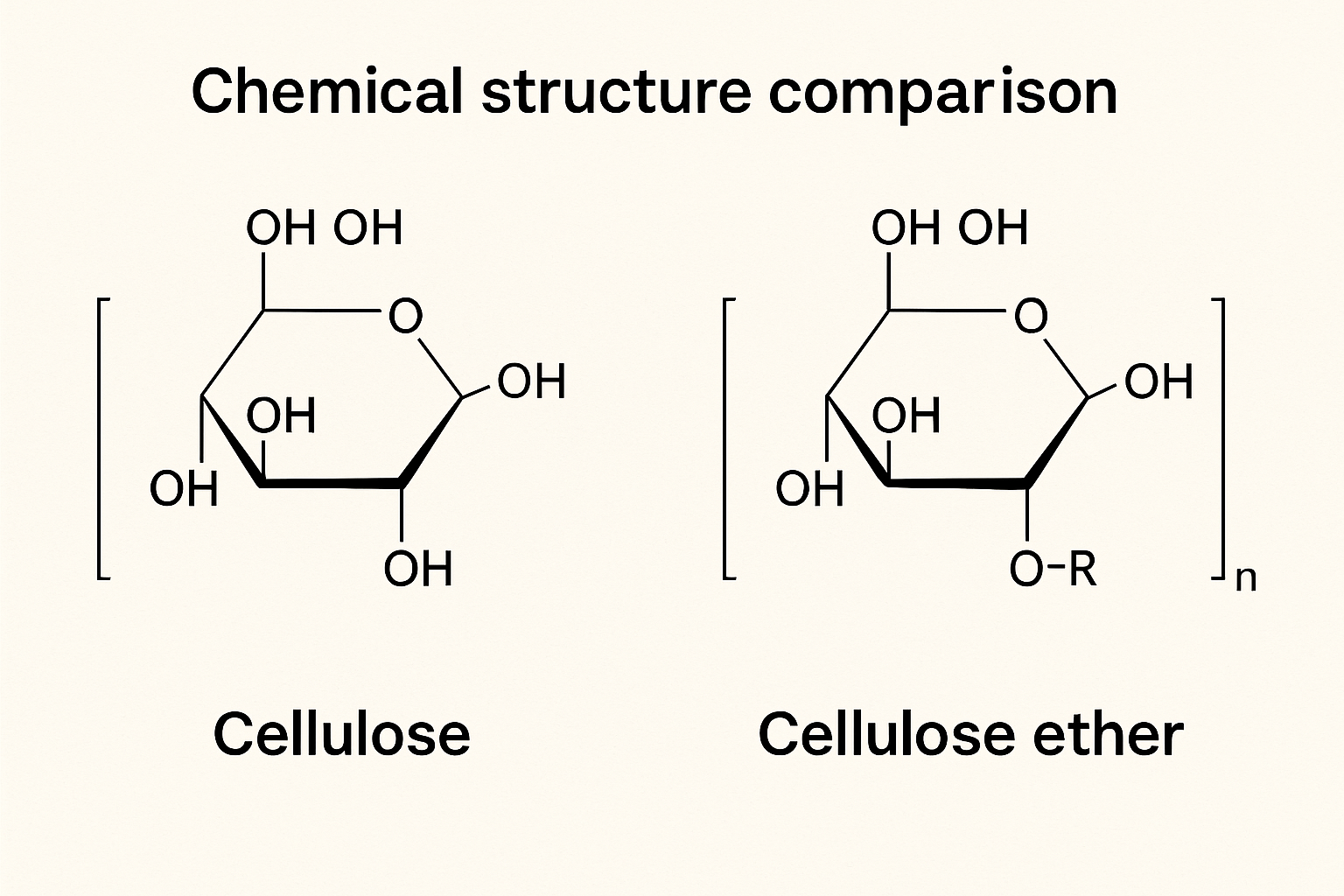

Unlike HPMC or HEC, Sodium Carboxymethyl Cellulose has carboxymethyl groups (-CH2-COOH) attached to some hydroxyl groups of the cellulose backbone, giving it anionic properties. This unique chemical structure provides CMC with superior stability in high-salt environments2, excellent water retention, and enhanced binding capabilities compared to other cellulose derivatives.

When I first started working with cellulose ethers, I was amazed by how significantly the chemical structure impacts performance. CMC stands out because of its ionic nature, which creates strong interactions with water molecules and charged surfaces. This gives it unique advantages in specific applications.

Key Structural Differences

| Property | CMC | HPMC | HEC |

|---|---|---|---|

| Chemical Groups | Carboxymethyl (-CH2-COOH) | Hydroxypropyl and Methyl | Hydroxyethyl |

| Ionic Nature | Anionic | Non-ionic | Non-ionic |

| Salt Tolerance | Excellent | Moderate | Moderate |

| Temperature Stability | High | Forms gel at high temp | Moderate |

| Acid Stability | Lower | Higher | Moderate |

The carboxymethyl groups give CMC its distinctive properties. During manufacturing, we carefully control the degree of substitution (DS) - the average number of hydroxyl groups substituted per anhydroglucose unit. This typically ranges from 0.4 to 1.4, with higher DS values increasing water solubility and stability in salt solutions. This precise control allows us to tailor CMC for specific applications - something I've found crucial when helping clients solve formulation challenges in industries from food processing to oil drilling.

How is Sodium Carboxymethyl Cellulose Manufactured for Industrial Use?

Many customers I meet are unaware of how production methods affect CMC quality. This knowledge gap often leads them to purchase inconsistent products that don't perform reliably in their applications.

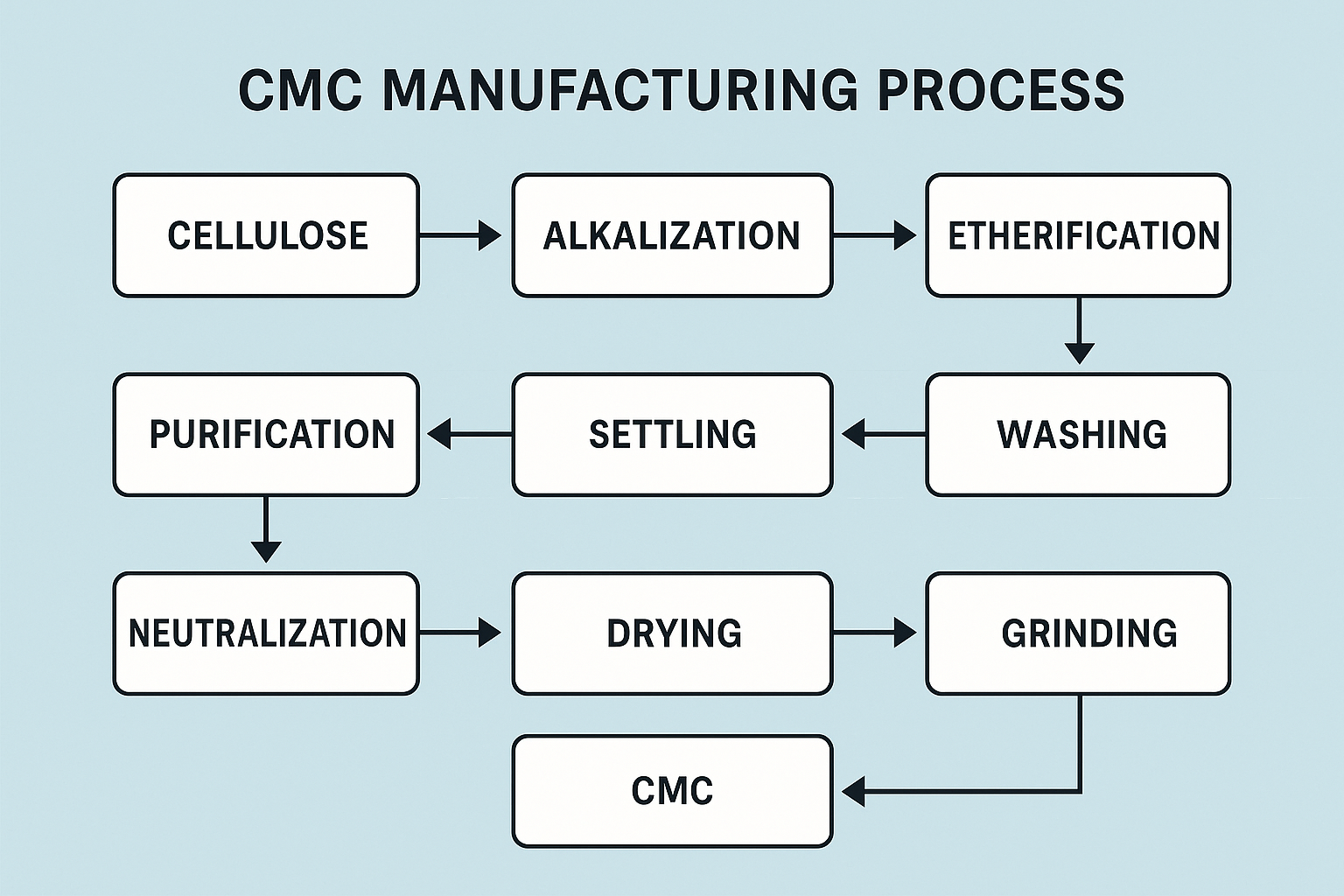

Sodium Carboxymethyl Cellulose is produced through a two-step process: first, cellulose from cotton or wood pulp is treated with sodium hydroxide to create alkali cellulose; second, sodium monochloroacetate reacts with this intermediate to form CMC. The resulting product is then purified, dried, and ground to specific particle sizes based on application requirements.

I've spent countless hours on our production floors at Kehao, observing and refining each manufacturing step. The quality of the raw cellulose significantly impacts the final product. We typically source high-grade cotton linters or refined wood pulp with high alpha-cellulose content (>95%) to ensure consistent quality.

Critical Production Parameters

The reaction conditions must be precisely controlled to achieve the desired degree of substitution (DS) and uniform substitution across the cellulose chain. Temperature, reaction time, alkalinity, and reagent ratios all play crucial roles. For instance, increasing the ratio of sodium monochloroacetate to cellulose typically increases DS, while higher reaction temperatures can lead to degradation of the cellulose backbone.

After the etherification reaction, multiple washing steps remove by-products and unreacted materials. This purification process is particularly important for food, pharmaceutical, and personal care applications, where residual chemicals could pose safety concerns. We operate different production lines with varying levels of purification based on the intended application.

The final drying and milling processes determine the particle size distribution and flow properties of the CMC powder. Fine grinding produces CMC that dissolves more quickly but can create dust issues during handling. Coarser grades flow better but take longer to hydrate fully. These physical characteristics are just as important as chemical properties in many applications.

What Are the Key Applications of Sodium Carboxymethyl Cellulose?

I regularly hear from potential customers who aren't fully utilizing CMC's potential in their products. They're often unaware of how this versatile polymer could solve multiple formulation challenges simultaneously.

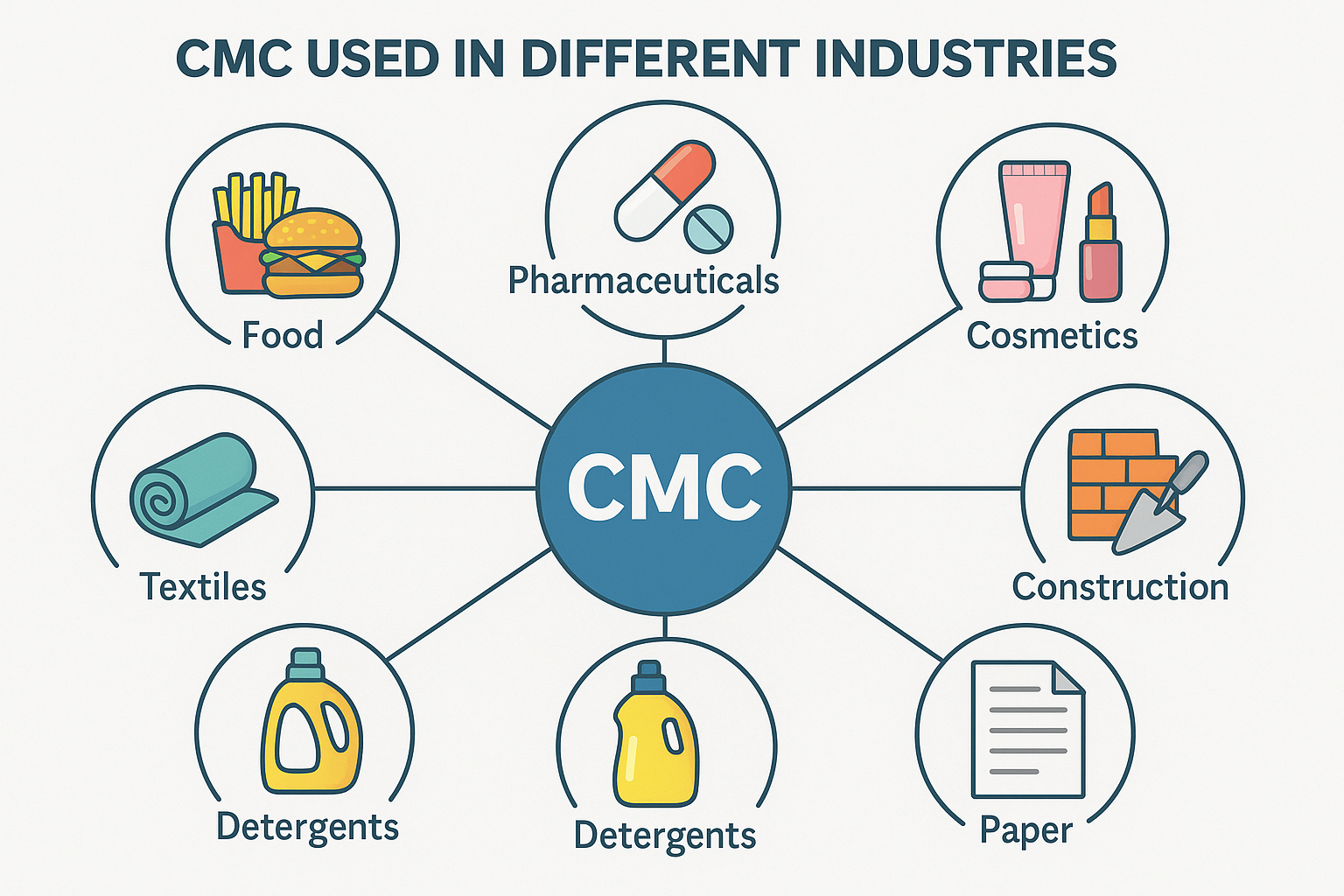

Sodium Carboxymethyl Cellulose serves as a thickener, stabilizer, and water retention agent across diverse industries. In construction, it improves workability and adhesion in tile adhesives and mortars. For food products, it prevents ice crystal formation and extends shelf life. In drilling fluids, CMC controls viscosity and reduces fluid loss, while in detergents, it supports soil suspension and prevents redeposition.

With over 15 years in the industry, I've seen CMC transform product performance across numerous applications. The versatility of this polymer continues to amaze me, especially as we develop new grades for emerging markets.

Construction Industry Applications

In construction materials, CMC provides critical functionality in products ranging from tile adhesives to cement-based renders. The water retention properties ensure proper cement hydration, even in hot or dry conditions, preventing premature drying that would weaken the final structure. I've worked with major mortar manufacturers who were able to extend their products' open time by 30-40% after switching to our optimized CMC grades.

The thickening effect also improves sag resistance, allowing for thicker application layers without slumping. This is particularly valuable in vertical tiling applications. Additionally, CMC enhances the adhesive properties by forming hydrogen bonds with both the substrate and the adhesive components, significantly improving bond strength.

For our customers in Saudi Arabia and UAE, where harsh climatic conditions pose challenges, we've developed specialized grades with enhanced stability at higher temperatures and improved resistance to enzymatic degradation.

| Construction Application | CMC Benefits | Typical Dosage |

|---|---|---|

| Tile Adhesives | Water retention, improved adhesion, extended open time | 0.2-0.5% |

| Cement Renders | Workability, reduced cracking, water retention | 0.1-0.3% |

| Joint Fillers | Improved consistency, crack resistance | 0.3-0.6% |

| Gypsum Products | Setting time control, improved workability | 0.1-0.4% |

What Factors Should You Consider When Selecting a CMC Grade?

I've seen many customers waste time and money using inappropriate CMC grades. Without understanding these key parameters, they end up with products that don't meet their performance requirements or create processing issues.

When selecting a CMC grade, focus on viscosity, degree of substitution (DS), purity, particle size, and pH stability. Viscosity determines thickening power, DS affects solubility and salt tolerance, purity matters for regulated applications, particle size impacts dissolution rate, and pH stability ensures performance across varying conditions. These properties must match your specific application requirements.

After helping hundreds of clients optimize their formulations, I've learned that matching CMC properties to application requirements is crucial. One food manufacturer I worked with struggled with poor texture until we identified that their process needed a higher-viscosity grade than they were using.

Understanding Viscosity Specifications

Viscosity is typically the first specification customers look at, but it's often misunderstood. CMC viscosity is measured under standardized conditions (usually 1% or 2% solution at 25°C) and can range from 5-15 cPs for low-viscosity grades to over 2000 cPs for high-viscosity types. However, the behavior in actual applications may differ significantly depending on other ingredients, processing conditions, and pH.

The viscosity profile across different shear rates (rheological behavior) is equally important. Some applications require a product that thins under shear (pseudoplastic behavior) for easy processing but recovers viscosity at rest. Others need consistent viscosity regardless of shear (Newtonian behavior). At Kehao, we provide detailed rheological data to help clients match CMC grades to their specific processing equipment and end-use requirements.

Temperature stability of viscosity also varies between grades. Standard CMC maintains reasonable viscosity at elevated temperatures, unlike some other cellulose ethers that gel when heated. This makes CMC valuable in hot-process applications. However, prolonged exposure to very high temperatures can cause degradation and viscosity loss.

The degree of substitution affects not just solubility but also compatibility with other ingredients, especially in the presence of salts or competing ions. Higher DS grades (0.8-1.2) generally offer better stability in high-salt environments like seen in detergent formulations or food products with high mineral content.

Conclusion

Sodium Carboxymethyl Cellulose stands out among cellulose ethers for its unique anionic character and versatile functionality. By understanding its properties, production methods, and application requirements, you can select the optimal grade for your specific needs.