Selecting the wrong cellulose ether for your mortar can lead to project failures, wasted materials, and costly rework. Many manufacturers struggle to determine which option best suits their specific application needs.

HPMC1 and HEMC2 differ primarily in their heat resistance capabilities. HEMC has a higher thermal gelation temperature (10-15°C higher than HPMC), making it more suitable for hot climate applications and intense mechanical mixing, while HPMC offers better cost efficiency for standard applications.

When I first started formulating mortars, I made costly mistakes by treating these products as interchangeable. Let me guide you through their differences to help you avoid similar issues and make informed decisions for your specific mortar applications.

Understanding HPMC1 vs HEMC2: What Makes Them Different?

I've seen many factories rush into production decisions without understanding the chemical nature of these additives. This oversight often leads to product failures and customer complaints that could easily be avoided.

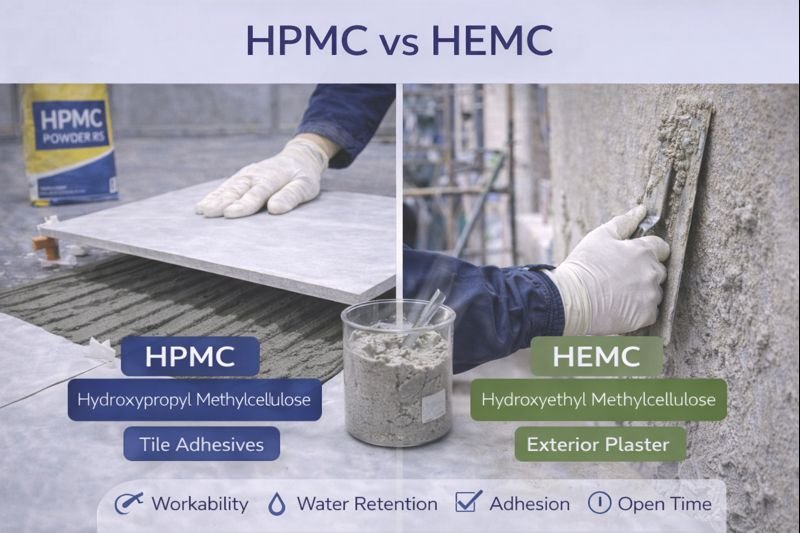

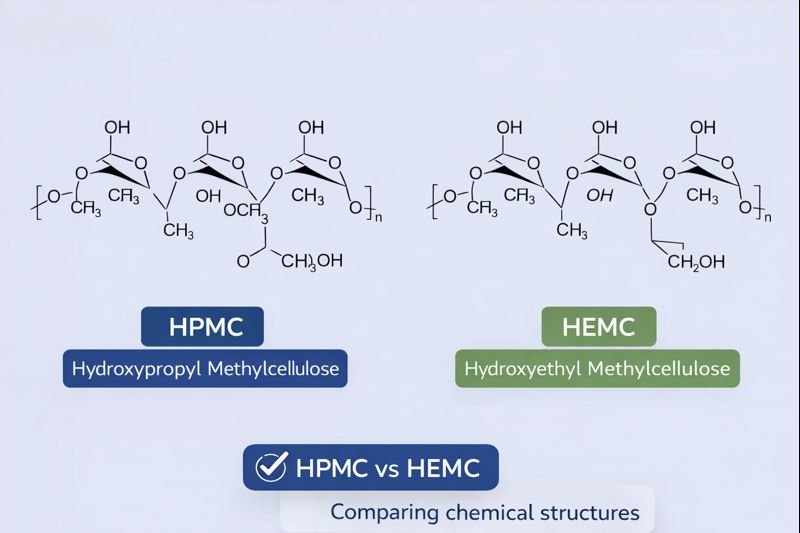

HPMC (Hydroxypropyl Methylcellulose) and HEMC (Hydroxyethyl Methylcellulose) are both cellulose ethers that work as water retention agents and rheology modifiers, but HEMC contains hydroxyethyl groups instead of hydroxypropyl groups, giving it different thermal properties.

When we look at these materials at the molecular level, the difference becomes clear. Their distinct chemical structures result in varying performance characteristics that significantly impact mortar behavior. The substitution of hydroxypropyl with hydroxyethyl groups in HEMC creates noticeable differences in thermal sensitivity, water retention, and workability.

Key Property Comparisons

| Property | HPMC | HEMC |

|---|---|---|

| Thermal Gelation Temperature | Lower (60-70°C) | Higher (70-85°C) |

| Cost | Generally lower | Usually 10-15% higher |

| Water Retention | Excellent | Excellent, slightly better at high temperatures |

| Workability | Good | Better 'slippery' feel |

| Thickening Efficiency | Higher at same viscosity | Slightly lower |

| Compatibility with Additives | Good | Excellent |

I've worked with manufacturers in Saudi Arabia who switched from HPMC to HEMC for their tile adhesives specifically because the local installation temperatures frequently exceeded 40°C. This simple change reduced their customer complaints about premature drying by nearly 70%. The higher thermal gelation point of HEMC prevented the mortar from losing its water retention capabilities during the critical open time window.

Functions and Applications: Where Does Each Excel?

Many mortar manufacturers I consult with make the mistake of sticking with one cellulose ether for all their product lines. This one-size-fits-all approach often compromises performance in specific applications.

HPMC works best in standard interior plasters, masonry mortars, and general-purpose applications where cost efficiency is crucial. HEMC shines in specialty applications like high-performance tile adhesives, EIFS (External Insulation Finishing Systems)3, and mortars used in hot climate regions.

I've witnessed the practical differences while working with clients across various climate zones. In moderate climates, HPMC performs admirably in most standard applications. However, when I helped develop formulations for projects in the UAE and Vietnam, HEMC proved to be significantly more reliable despite the higher cost.

Application-Specific Recommendations

The selection between these two cellulose ethers often depends on the specific demands of your application. Let me break down the most common scenarios:

| Application | Recommended Choice | Reasoning |

|---|---|---|

| Basic Rendering Mortars | HPMC | Cost-effective with sufficient performance |

| Tile Adhesives (Standard) | HPMC | Good water retention, adequate open time |

| Tile Adhesives (Premium) | HEMC | Better slip resistance, extended open time |

| EIFS Systems | HEMC | Superior stability in varied weather conditions |

| Self-Leveling Compounds | HEMC | Better flow properties and compatibility with superplasticizers |

| Spray Plasters | HEMC | Improved workability and consistency during pumping |

| Gypsum-Based Products | HPMC/HEMC | Depends on specific performance requirements |

One of my clients in Singapore switched from HPMC to HEMC in their exterior render after experiencing frequent callbacks due to cracking in the intense tropical heat. The higher thermal stability of HEMC allowed for more consistent water retention during the critical curing phase, reducing defects by approximately 35%.

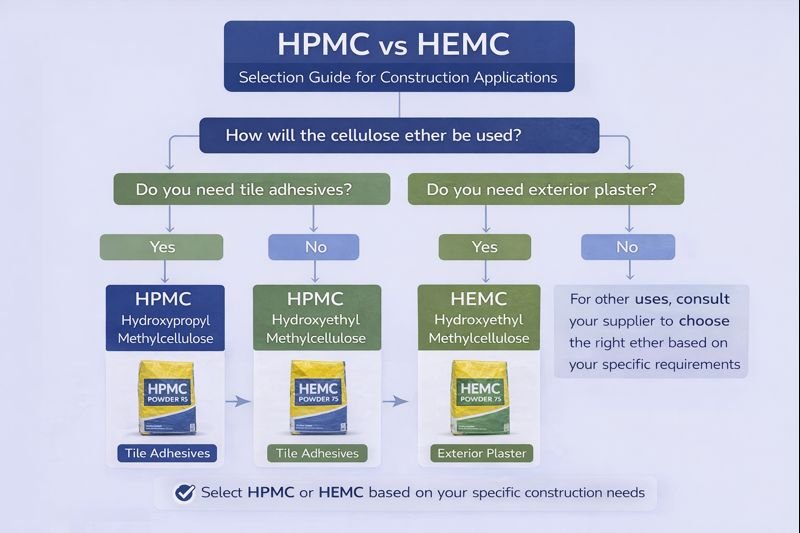

How to Choose HPMC vs HEMC for Your Specific Needs?

I've seen too many manufacturers waste thousands of dollars on inappropriate cellulose ether selections, leading to formulation problems, production delays, and unhappy customers.

Choose HPMC for cost-effective applications in moderate climates where standard performance is acceptable. Select HEMC when working in hot environments, when mechanical mixing is intense, or for premium products requiring extended workability and superior water retention under stress.

The decision between HPMC and HEMC isn't just about immediate performance—it affects the long-term reputation of your products in the market. When I formulate mortars, I always consider the entire lifecycle and application environment.

Practical Selection Factors

When helping clients make this important decision, I consider several critical factors:

-

Application Temperature Range: If your product will be used in environments regularly exceeding 35°C, HEMC's higher thermal gelation temperature provides a significant advantage.

-

Mechanical Stress: The high-shear mixing common in modern construction can generate heat. HEMC withstands this better, maintaining its water retention properties.

-

Open Time Requirements: Premium tile adhesives often need extended open time. HEMC typically provides 15-30% longer working time under challenging conditions.

-

Budget Constraints: For basic applications where performance demands are modest, HPMC offers an excellent balance of performance and cost.

-

Formulation Compatibility: HEMC generally shows better compatibility with other additives like redispersible polymer powders and superplasticizers, which is crucial for sophisticated formulations.

I remember consulting with a factory in Mexico that was experiencing inconsistent quality in their tile adhesives. Their production occurred in a non-air-conditioned facility where temperatures fluctuated significantly. By switching from HPMC to HEMC, they eliminated the seasonal issues that had been plaguing their quality control process.

Conclusion

The choice between HPMC and HEMC comes down to understanding your specific application needs. While HPMC offers cost advantages for standard applications, HEMC provides superior performance under heat stress and in premium applications. Make your selection based on application environment, performance requirements, and budget constraints.

FAQ

Can I directly substitute HEMC for HPMC in my formulation?

No. Although similar, they have different thickening efficiencies and rheological profiles. Formulations need adjustment when switching.

Is the higher cost of HEMC always justified?

Only for applications where its thermal stability and workability advantages are needed. For basic applications in moderate conditions, HPMC is often more cost-effective.

How do these materials impact environmental sustainability?

Both are derived from renewable sources and biodegradable, but production processes vary. Request environmental certification from your supplier.

Can I blend HPMC and HEMC?

Yes, some manufacturers create custom blends to optimize performance/cost ratio for specific applications.

Do viscosity grades work the same way for both products?

Generally yes, but HEMC may require slightly different dosages to achieve similar viscosity in the final application.

-

Explore this link to understand HPMC's benefits and applications in construction, ensuring you make informed choices. ↩ ↩

-

Learn about HEMC's unique properties and applications to enhance your mortar formulations effectively. ↩ ↩

-

Explore EIFS technology to understand its benefits in energy efficiency and insulation. ↩